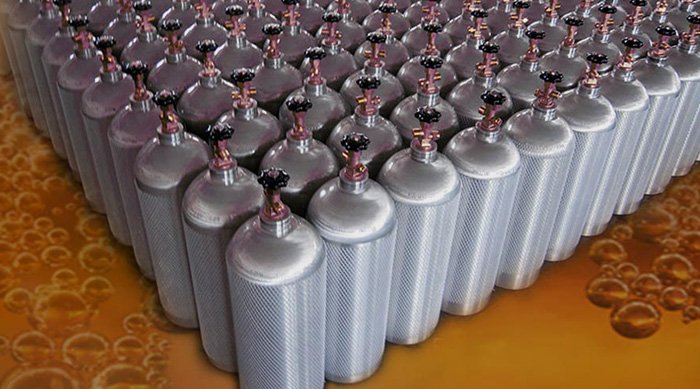

Aluminium Cylinders V/S Steel Cylinders

Why Aluminium Cylinders Are Better Than Steel Cylinders?

Aluminium vs Steel Cylinder | Aluminium Cylinders Advantage

Why Aluminium Cylinders Are Better Than Steel Cylinders Internal and external corrosion are the main causes of steel cylinders failing inspection or test.

Aluminium Cylinders Fail Less Often.

More importantly, internal corrosion activity will reduce the oxygen content of the air, In the USA we have two examples of oxygen depletion in steel cylinders (corrosion is more rapid in steel)

- Following three months of storage a, corroded cylinder contained only 15% oxygen

A Nearly Deadly Deficiency - Analysis of a dead diver’s air supply in a heavily corroded steel cylinde revealed

A Deadly 6% Oxygen Content

The University of Rhode Island’s study of cylinder internal corrosion reveals that :

Under equal conditions of moisture in cylinders, aluminium cylinders are much better, so air stored in aluminium cylinders may retain its quality longer

Why COz steel cylinder get corrsion?

- When the carbon dioxide becomes moist through wet gas supply or mixing with entrapped liquid in the cylinders, the carbonic acid that is formed will corrode a steel cylinder Rust develops that will contaminate the carbon dioxide gas used to dispense the beverage, and can lead to cylinder failure if undetected.

- Aluminium cylinders, on the other hand, are not affected by carbonic acid, and no corrosion will occur.

Carbon dioxide gas reacts with water to form carbonic acid. According to the ASM( American Society for Metals) Metals Handbook (1, 2, 3), aluminium and brass are not attacked by carbonic acid, but steel will corrode.

The American Compressed Gas Association in, Pamphlets G-6 and G-6.3 (4,5), warns that wet carbon dioxide will cause severe corrosion in steel cylinders Only dry carbon dioxide should ever be filled in to steel cylinders. Additionally precautions should be taken to drain cylinder suspected of containing liquids before’ filling, and special care should be taken when retesting steel cylinders that have been used in carbon dioxide service. - Cylinder Manufacturer representative in Germany has reported that the German Authorities were so concerned with the safety of steel carbon dioxide cylinders after several accidents that they insisted on every steel carbon dioxide cylinder being opened and checked before refilling.

- “Carbon dioxide is only about one tenth as corrosive as oxygen, and in natural waters, the carbon dioxide concentration is important only as it affects the solubility and precipitation of calcium carbonate. The chief detrimental effects of carbon dioxide arise from its great solubility in water and high chemical reactivity with water. When process water comes in contact with a continuing or concentrated source of carbon dioxide, such as occurs in certain steam-powered systems or in some chemical or manufacturing plants, the solubility and reactivity of carbon dioxide lead to formation of dilute carbonic acid solution.

At 20 degC (68degF), the solubility of carbon dioxide in water is 900 mL/L – by contrast, the solubility of oxygen is about 6 mL/L. Because of its high solubility, sufficient carbon dioxide can be dissolved in pure water to drive the pH below 6.0, where acid corrosion and hydrogen evolution can occur when the water is in contact with steel.” - “The hydrostatic test shall be performed at 5/3 of the stamped service pressure. The internal visual inspection shall be carefully performed to detect harmful corrosion because wet carbon dioxide can rapidly corrode a steel cylinder.”

- “Carbon dioxide cylinders are used extensively in the manufacturing and distribution of carbonated beverages. It is possible to have water flow back into the cylinders in some circumstances. When water collects in the bottom of the cylinder it combines with carbon dioxide to form carbonic acid. This causes internal corrosion and potential failure”.

- “Corrosion resistance of aluminium alloys in high-purity water is not significantly decreased by dissolved carbon dioxide or oxygen in the water or, in most cases, by the various chemicals added to high-purity water in the steam power industry to provide the required compatibility with steel.” “Carbonic acid has negligible action on aluminium. Aluminium equipment is in use handling carbonated beverages. Aluminium steam – condensate lines have replaced steel in installations where carbon dioxide is associated with the steam.”

- In addition to affecting the purity of the carbon dioxide gas, such contaminants react with the carbon dioxide to form carbonic acid, and the rust corrosion of steel cylinders will result. Corrosion with this type of contamination is negligible in aluminium cylinders containing a positive pressure of carbon dioxide. Corrosive attack will generally be limited when aluminium alloys are exposed to these types of environments

Applications

Leading manufacturer and exporter of Seamless Aluminium High Pressure Cylinders Aluminium containers, bottles & aerosol can.

High Pressure Cylinders

Learn More

Disposable / Low Pressure Cylinders

Learn More

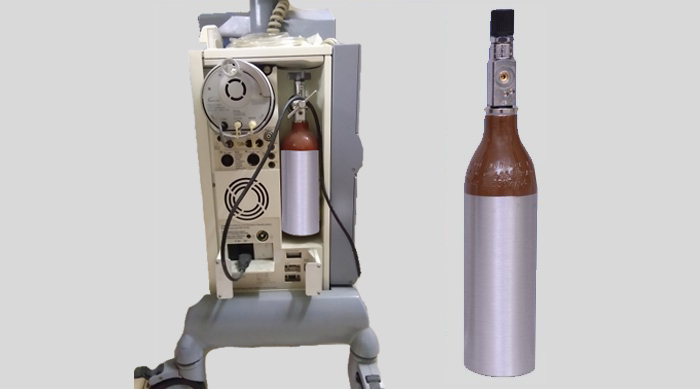

Medical

Learn More

Homecare

Learn More

Scuba

Learn More

Beverages

Learn More

Fire Extinguisher

Learn More

Sports & Fitness / Tracking

Learn More

Paint ball

Learn More

IABP Machine

Learn More

Balloon

Learn More